Xulashada agabka PCB-ga iyo qaybaha elektiroonigga ah waa wax la bartay, sababtoo ah macaamiishu waxay u baahan yihiin inay tixgeliyaan arrimo badan, sida tilmaamayaasha waxqabadka qaybaha, shaqooyinka, tayada iyo darajada qaybaha.

Maanta, waxaan si nidaamsan u soo bandhigi doonaa sida saxda ah ee loo doorto agabka PCB iyo qaybaha elegtarooniga ah.

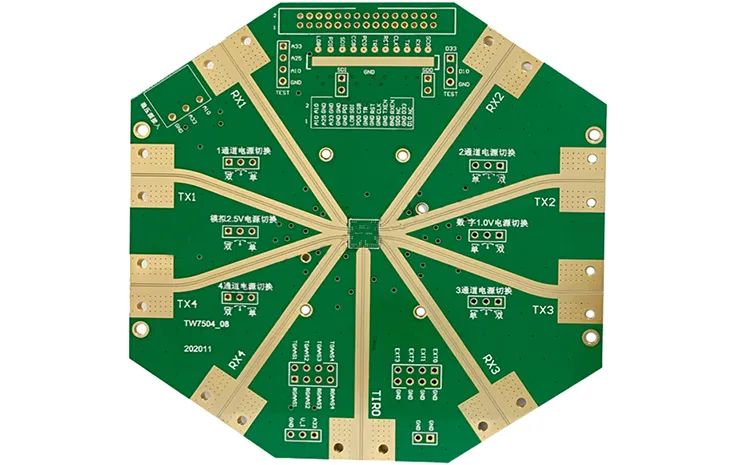

Xulashada walxaha PCB

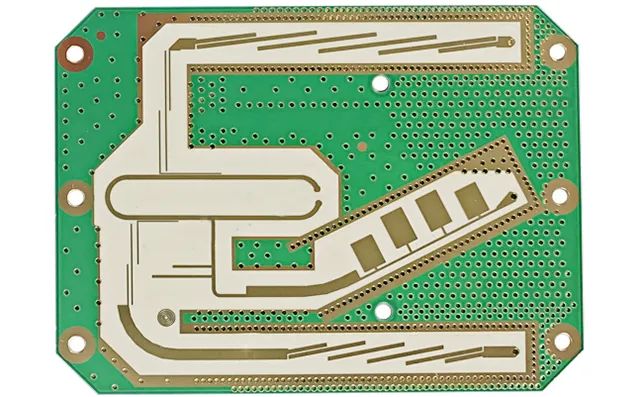

FR4 epoxy fiberglass tirtirada waxaa loo isticmaalaa alaabta elektiroonigga ah, polyimide fiberglass tirshadaha waxaa loo isticmaalaa heerkulka jawi sare ama loox wareeg ah dabacsan, iyo polytetrafluoroethylene fiberglass tirtiraya ayaa looga baahan yahay wareegyada soo noqnoqda sare. Alaabooyinka elektiroonigga ah ee leh shuruudaha kala-baxa kulaylka sare, biraha waa in la isticmaalo.

Arrimaha ay tahay in la tixgeliyo marka la dooranayo agabka PCB:

(1) Substrate leh heerkul sare oo dhalo ah (Tg) waa in si habboon loo doortaa, Tg-guna waa inuu ka sarreeyaa heerkulka hawlgalka wareegga.

(2) Isku-dhafka hoose ee ballaarinta kulaylka (CTE) ayaa loo baahan yahay. Sababtoo ah isku dheelitir la'aanta ballaarinta kulaylka ee jihada X, Y iyo dhumucda, way fududahay in la keeno PCB-ga, waxayna sababi doontaa dillaaca godka birta iyo dhaawaca qaybaha xaaladaha halista ah.

(3) Iska caabbinta kulaylka sare ayaa loo baahan yahay. Guud ahaan, PCB waxaa looga baahan yahay inay lahaato iska caabin kulayl oo ah 250 ℃ / 50S.

(4) Fiican wanaagsan ayaa loo baahan yahay. Shuruudaha bogga dagaal ee PCB ee SMT waa <0.0075mm/mm.

(5) Marka la eego waxqabadka korantada, wareegyada soo noqnoqda ee sarreeya waxay u baahan yihiin xulashada maaddooyinka leh dielectric joogto ah iyo luminta dielectric hooseeya. Iska caabbinta dahaarka, xoogga korantada, caabbinta arc si loo buuxiyo shuruudaha alaabta.

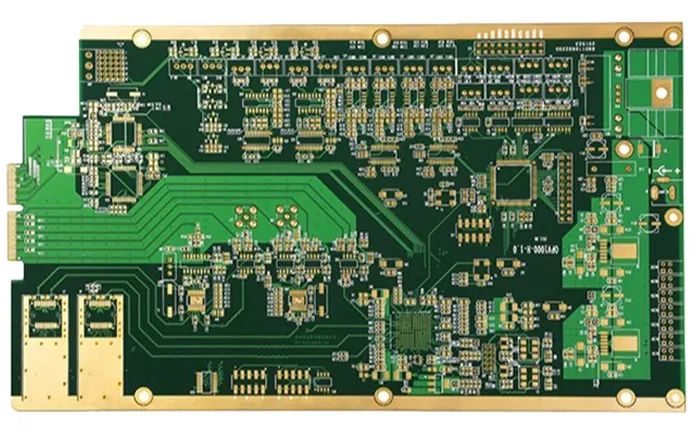

Doorashada qaybaha elektarooniga ah

Marka lagu daro buuxinta shuruudaha waxqabadka korantada, xulashada qaybaha waa inay sidoo kale buuxiyaan shuruudaha isu-ururinta dusha sare ee qaybaha. Laakiin sidoo kale marka loo eego shuruudaha qalabka wax soo saarka ee wax soo saarka iyo habka wax soo saarka si loo doorto qaabka baakadaha qaybta, xajmiga qaybta, foomka baakadaha.

Tusaale ahaan, marka isku-dhafka cufnaanta sare uu u baahan yahay xulashada qaybaha yaryar ee khafiifka ah: haddii mashiinka wax lagu dhejiyo aanu lahayn feedhiyaha xajmiga ballaaran, qalabka SMD ee baakadaha timaha lama dooran karo;

Waqtiga boostada: Jan-22-2024