Kulaylka kuleyliyaha guddiga wareegga PCB waa xiriiriye aad muhiim u ah, haddaba waa maxay xirfadda kulaylka ee guddiga wareegga PCB, aan si wadajir ah uga wada hadalno.

Guddiga PCB-ga oo si weyn loogu isticmaalo kulaylka iyada oo loo marayo looxa PCB laftiisa waa maro-daboolan/epoxy-glaas substrate ama substrate maro dhalada resin phenolic, waxaana jira cadad yar oo xaashi ku salaysan oo naxaas ah oo la isticmaalo. Inkasta oo substrates-yadani ay leeyihiin sifooyin koronto oo heer sare ah iyo sifooyin wax-soo-saar leh, waxay leeyihiin kuleyl xumo liidata, iyo sida dariiqa kulaylka ee qaybaha kulaylka sare, waxay adagtahay in la fili karo in ay kuleyl u qabtaan PCB laftiisa, laakiin si ay u daadiyaan kuleylka dusha sare ee qaybta hawada ku wareegsan. Si kastaba ha noqotee, sida alaabada elektiroonigga ah ay soo galeen xilligii qaybta miniaturization-ka, rakibidda cufnaanta sare, iyo kulaylka sare ee kuleylka, kuma filna in lagu tiirsanaado oo keliya dusha sare ee meel aad u yar si loo kala saaro kuleylka. Isla mar ahaantaana, sababtoo ah isticmaalka ballaaran ee qaybaha dusha sare ee sida QFP iyo BGA, kulaylka ka soo baxa qaybaha waxaa lagu gudbiyaa guddiga PCB tiro badan, sidaas darteed, habka ugu wanaagsan ee lagu xalliyo kulaylka waa in la hagaajiyo awoodda kulaylka ee PCB lafteeda xiriir toos ah oo leh walxaha kuleylka, kaas oo la kala qaado ama loo qaybiyo iyada oo loo marayo guddiga PCB.

Qaabaynta PCB

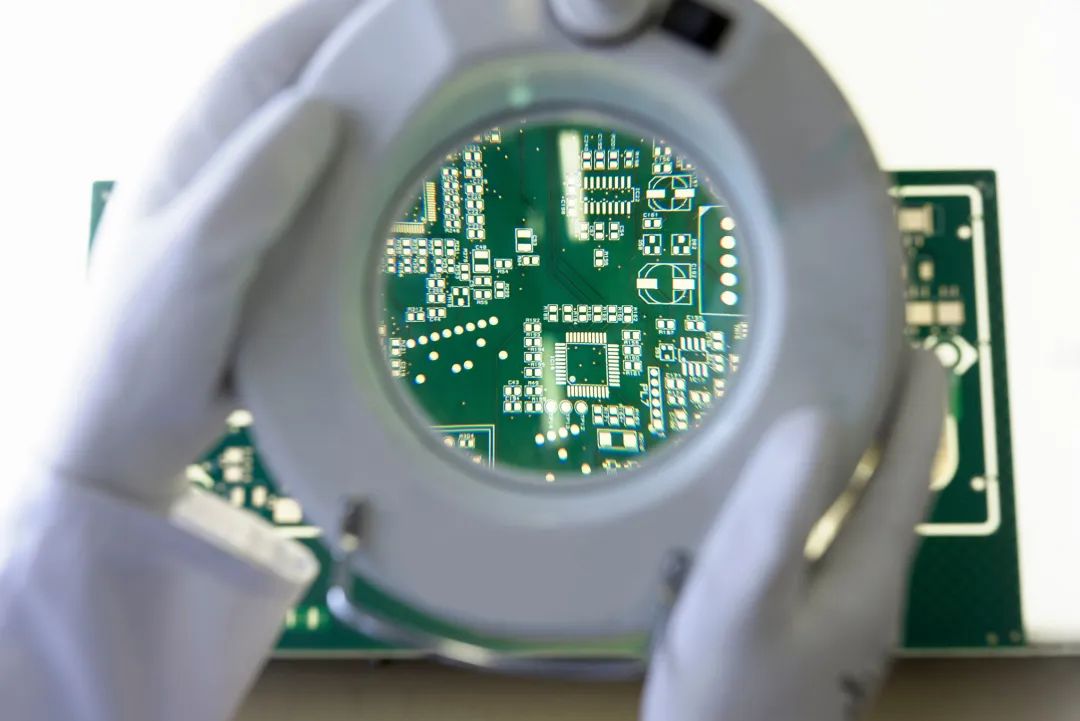

a, Qalabka xasaasiga ah ee kulaylka waxaa la dhigayaa aagga hawada qabow.

b, Qalabka lagu ogaanayo heerkulka waxaa la dhigayaa meesha ugu kulul.

c, Aaladaha ku jira isla guddiga daabacan waa in loo habeeyaa sida ugu macquulsan iyadoo loo eegayo xajmiga kulaylkiisa iyo heerka kuleylka kuleylka, kulaylka yar yar ama qalabka caabbinta kulaylka liidata (sida transistor-ka yaryar, wareegyada isku dhafan ee cabbirka yar, capacitors electrolytic, iwm) ayaa la dhigayaa inta ugu badan ee socodka hawada qaboojinta ( gelitaanka), Aaladaha leh jiilka kulaylka weyn ama kuwa kuleyliyaha wanaagsan ee isku dhafan, iwm. dhanka hoose ee qulqulka qaboojinta.

d, jihada toosan, qalabka awoodda sare leh ayaa loo habeeyey sida ugu dhow ee suurtogalka ah cidhifka looxa daabacan si loo gaabiyo habka wareejinta kulaylka; Jihada toosan, qalabka awooda sare leh ayaa loo habeeyey sida ugu dhow ee suurtogalka ah ee looxa daabacan, si loo yareeyo saameynta qalabkan heerkulka qalabka kale marka ay shaqeynayaan.

e, kulaylka looxa daabacan ee qalabku wuxuu inta badan ku xiran yahay socodka hawada, markaa dariiqa socodka hawada waa in lagu daraa naqshadeynta, iyo qalabka ama guddiga wareegga daabacan waa in si macquul ah loo qaabeeyey. Marka hawadu socoto, had iyo jeer waxay u egtahay inay ku qulqulayso halka iska caabbinta yar tahay, markaa marka la habeynayo aaladda sabuuradda wareegga daabacan, waa lagama maarmaan in laga fogaado in hawo weyn laga tago meel gaar ah. Habaynta looxyada wareegyada daabacan ee badan ee mashiinka oo dhan waa in sidoo kale fiiro gaar ah u yeeshaan dhibaatada isku midka ah.

f, Qalab badan oo heerkulka xasaasiga ah ayaa si fiican loogu dhejiyaa aagga heerkulka ugu hooseeya (sida hoose ee qalabka), ha dhigin meel ka sarraysa qalabka kuleyliyaha, qalabyo badan ayaa ugu fiican qaabka ugu fiican ee diyaaradda jiifka ah.

g, diyaari aaladda isticmaalka tamarta ugu sarreysa iyo kulaylka ugu weyn ee u dhow meesha ugu fiican ee kulaylka. Ha dhigin aaladaha kulaylka sare leh geesaha iyo cidhifyada looxa daabacan, ilaa aalad qaboojin lagu habeeyo agteeda. Markaad naqshadaynayso caabbinta awoodda, dooro qalab weyn sida ugu badan ee suurtogalka ah, oo hagaaji qaabka looxa daabacan si uu u helo meel ku filan oo kuleyl ah.

Waqtiga boostada: Mar-22-2024