Guud ahaan, way adagtahay in laga fogaado qadar yar oo ku guuldareysiga horumarinta, wax soo saarka iyo isticmaalka qalabka semiconductor.Iyadoo horumarinta joogtada ah ee shuruudaha tayada alaabta, falanqaynta guul-darradu waxay noqonaysaa mid aad iyo aad muhiim u ah.Iyadoo la falanqeynayo jajabyada khaaska ah ee fashilka, Waxay ka caawin kartaa naqshadeeyayaasha wareegga inay helaan cilladaha naqshadaynta qalabka, is-waafajinta hababka habka, naqshadda aan macquul ahayn ee wareegga wareegga ama khalkhalka ay sababtay dhibaatada.Baahida loo qabo falanqaynta fashilka ee aaladaha semiconductor waxaa inta badan lagu muujiyaa dhinacyada soo socda:

(1) Falanqaynta guul-darradu waa hab lagama maarmaan ah oo lagu go'aamiyo habka guul-darreysiga ee chip-ka aaladda;

(2) Falanqaynta guuldarradu waxay bixisaa aasaaska lagama maarmaanka ah iyo macluumaadka loogu talagalay ogaanshaha khaladka wax ku ool ah;

(3) Falanqaynta guuldarradu waxay siisaa macluumaadka jawaab celinta lagama maarmaanka u ah injineerada naqshadeynta si ay si joogto ah u hagaajiyaan ama u dayactiraan naqshadda chip oo ay uga dhigaan mid macquul ah si waafaqsan qeexida naqshadeynta;

(4) Falanqaynta guul darradu waxay bixin kartaa kabitaanka lagama maarmaanka u ah tijaabada soo saarista waxayna bixin kartaa saldhig macluumaadka lagama maarmaanka ah si loo wanaajiyo habka tijaabada xaqiijinta.

Falanqaynta fashilka ee diodes semiconductor, audions ama wareegyada isku dhafan, cabbirada korantada waa in la tijaabiyaa marka hore, ka dib kormeerka muuqaalka ee mikroskoobka indhaha, baakadaha waa in la saaraa.Iyadoo la ilaalinayo daacadnimada shaqada chip-ka, hoggaanka gudaha iyo dibedda, dhibcaha isku-xidhka iyo dusha sare ee chip waa in lagu hayaa ilaa inta suurtogalka ah, si loogu diyaargaroobo tallaabada xigta ee falanqaynta.

Isticmaalka iskaanka mikroskoobyada elektarooniga ah iyo spectrum tamarta si loo sameeyo falanqayntan: oo ay ku jiraan indho-indheynta qaab-dhismeedka qaab-dhismeedka yar-yar, raadinta dhibicda fashilka, indho-indheynta dhibicda cilladda iyo goobta, cabbirka saxda ah ee cabbirka joomatari-yar ee qalabka iyo qaybinta awoodda dusha qallafsan iyo xukunka macquulka ah ee iridda dhijitaalka ah wareegga (oo leh habka sawirka ka soo horjeeda danab);Isticmaal spectrometer tamarta ama spectrometer si aad u samayso falanqayntan waxay leedahay: falanqaynta halabuurka curiyaha microscopic, qaab dhismeedka walxaha ama falanqaynta wasakhaysan.

01. Cilladaha dusha sare iyo gubashada aaladaha semiconductor

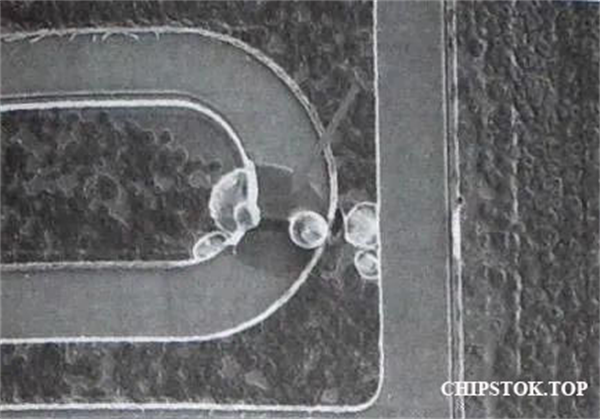

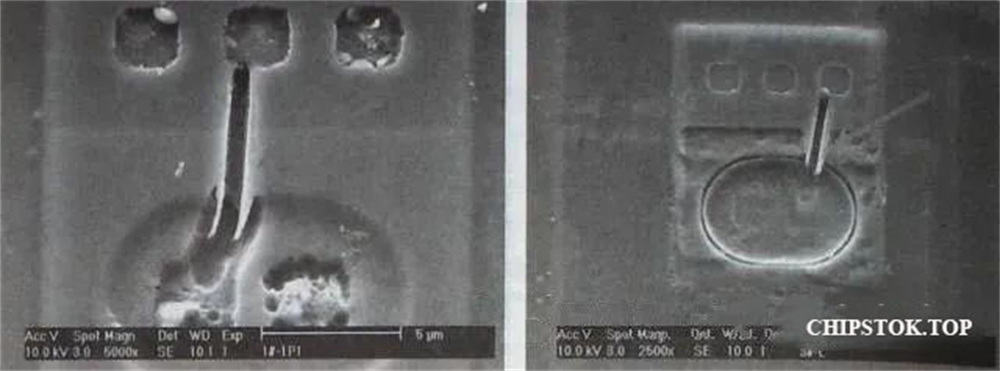

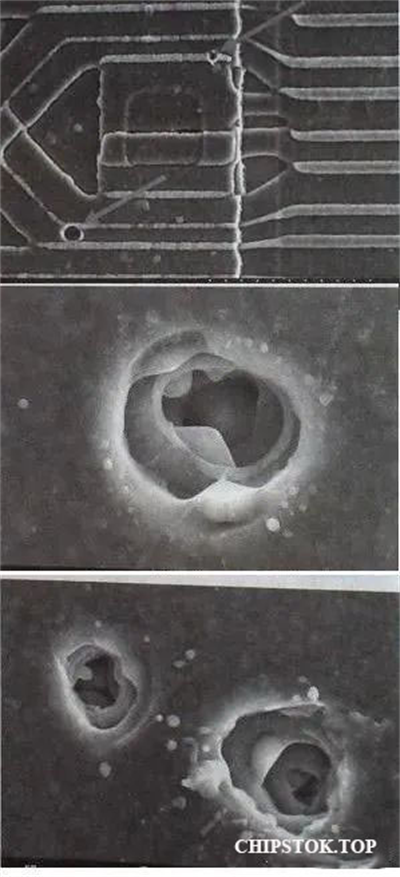

Cilladaha dusha sare iyo gubashada aaladaha semiconductor labaduba waa qaabab guuldarro caadi ah, sida ku cad sawirka 1, kaas oo ah cilada lakabka la safeeyey ee wareegga isku dhafan.

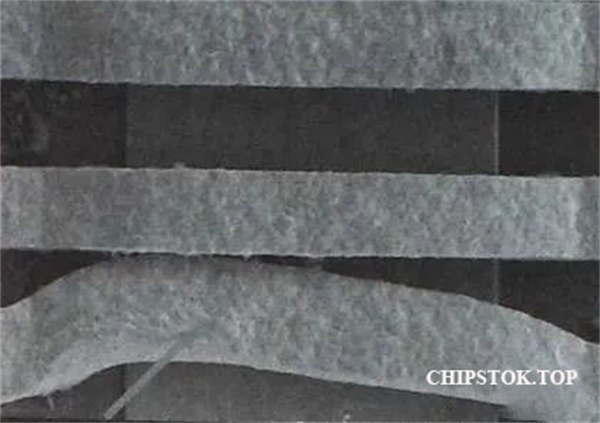

Jaantuska 2 wuxuu muujinayaa cilada dusha sare ee lakabka birta ah ee wareegga isku dhafan.

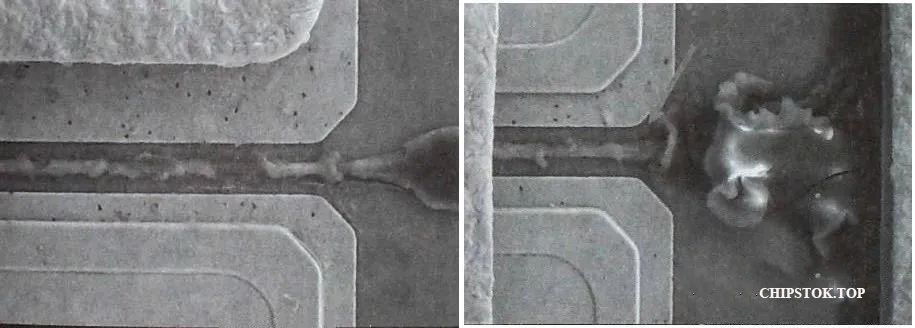

Jaantuska 3 waxa uu tusinayaa kanaalka burburay ee u dhexeeya labada xabbo ee birta ah ee wareegga isku dhafan.

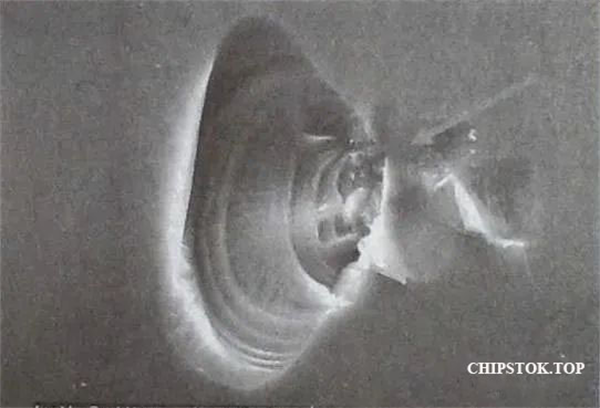

Jaantuska 4 waxa uu muujinayaa birta oo duntay iyo qallooc ku yimid buundada hawada ee aaladda microwave-ka.

Jaantuska 5 waxa uu tusinayaa gubasho la'aanta tuubada microwave-ka.

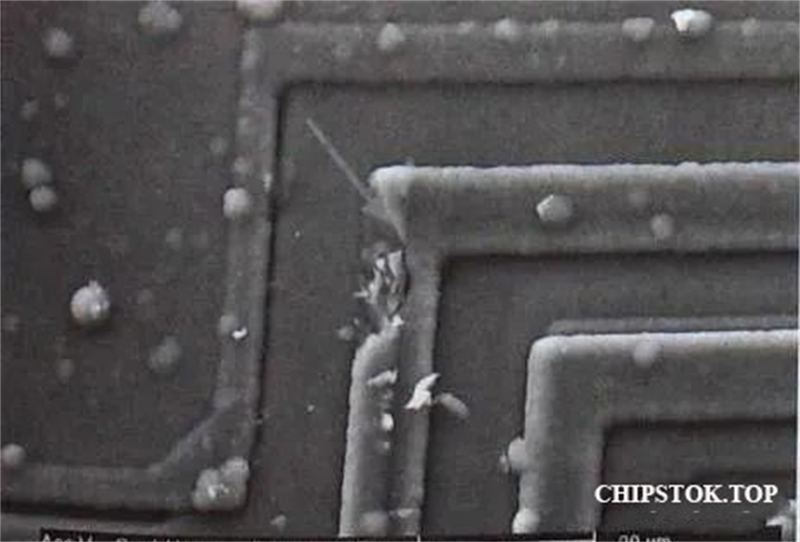

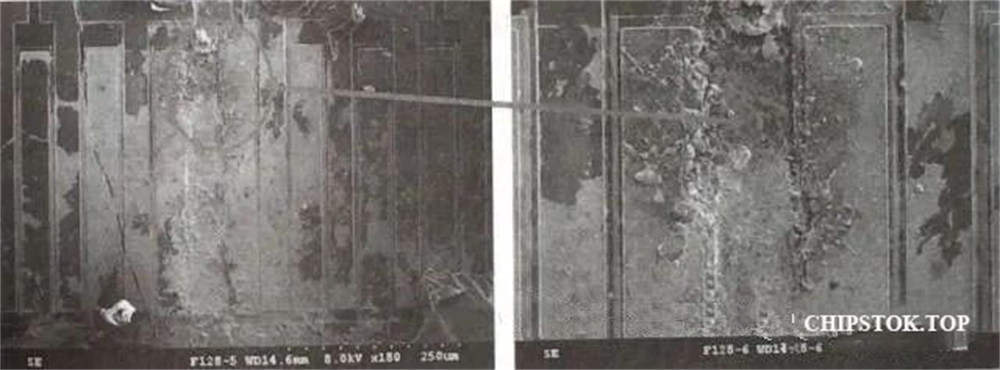

Jaantuska 6 waxa uu tusinayaa dhaawaca makaanikada ah ee soo gaadhay siligga korantada ee isku xidhan.

Jaantuska 7 waxa uu muujinayaa fur furka iyo cilada mesa diode

Jaantuska 8 wuxuu muujinayaa burburka diode-ka difaaca ee galinta wareegga isku dhafan.

Jaantuska 9 wuxuu muujinayaa in dusha sare ee chip-ka isku-dhafka ah ee isku-dhafka ah uu waxyeello u geysto saameynta farsamada.

Jaantuska 10 waxa uu tusinayaa qayb gubasho ah oo ka timid qalabka isku dhafka ah ee wareegga wareegga.

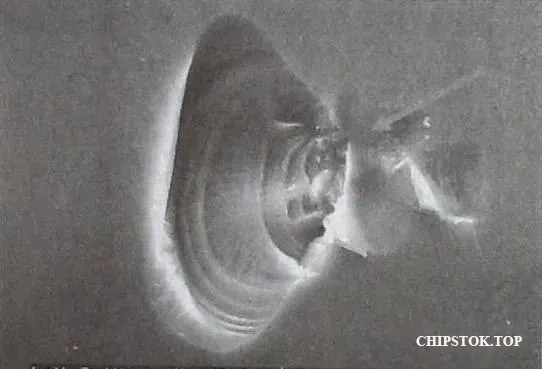

Jaantuska 11 wuxuu muujinayaa jajabkii diode-ka oo jabay oo aad u gubtay, iyo dhibcihii burburay waxay isu beddeleen xaalad dhalaalid.

Jaantuska 12 waxa uu muujinayaa gallium nitride mikrowayt tube chip chip oo gubtay, barta gubtayna waxa ay soo bandhigaysaa xaalad dhalaalaysa.

02. Burburka korantada

Aaladaha Semiconductor-ka ah ee wax soo saarka, baakadaha, gaadiidka ilaa looxa wareegga si loo geliyo, alxanka, isu-ururinta mishiinka iyo hababka kale waxay halis ugu jiraan koronto taagan.Habkan, gaadiidka ayaa waxyeello u geysanaya dhaqdhaqaaqa joogtada ah iyo soo-gaadhista fudud ee korantada taagan ee ay dhaliso dunida dibaddu.Sidaa darteed, fiiro gaar ah waa in la siiyaa ilaalinta korantada inta lagu jiro gudbinta iyo gaadiidka si loo yareeyo khasaaraha.

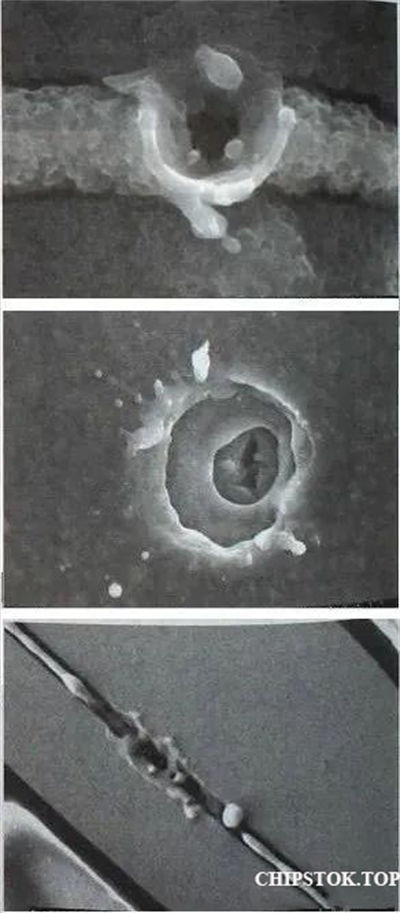

In aaladaha semiconductor leh tuubada MOS unipolar iyo MOS isku dhafan wareegga si gaar ah xasaasi u ah korontada taagan, gaar ahaan tuubada MOS, sababtoo ah iska caabin u gaar ah waa mid aad u sarreeya, iyo capacitance electrode-albaabka waa mid aad u yar, sidaas darteed aad bay u fududahay in la noqdo. ay saameysay korantada korantada ee dibadda ama soo saarista elektrostatic oo lagu dallaco, iyo sababta oo ah jiilka korantada, way adagtahay in la bixiyo qarashka waqtiga, Sidaa darteed, way fududahay in la keeno koronto joogto ah burburka degdega ah ee aaladda.Qaabka burburka korantada inta badan waa burburka xariifnimada korantada, taas oo ah, lakabka oksaydhka khafiifka ah ee shabagga ayaa go'ay, kaas oo samaynaaya dalool, kaas oo gaabinaya faraqa u dhexeeya shabagga iyo isha ama inta u dhaxaysa shabagga iyo qulqulka.

Marka loo eego MOS tube MOS awoodda burburka antistatic-ka ee isku-dhafan ee wareegga wareegga ayaa xoogaa ka wanaagsan, sababtoo ah terminalka wax-gelinta ee MOS ee wareegga isku-dhafka ah wuxuu ku qalabaysan yahay diode ilaalin ah.Marka uu jiro koronto weyn oo koronto ama koronto ku soo korodha inta badan diodes-ka difaaca ayaa loo rogi karaa dhulka, laakiin haddii danabku aad u sarreeyo ama hadda dhawaaqa degdega ah uu aad u weyn yahay, mararka qaarkood diodes-ka difaaca ayaa laftooda yeelan doona, sida ku cad jaantuska. 8.

Sawirada dhowrka ah ee lagu muujiyey jaantuska13 waa muuqaalka burburka korantada ee wareegga isku dhafan ee MOS.Meesha burburku waa mid yar oo qoto dheer, oo soo bandhigaysa xaalad shuban oo dhalaalaysa.

Jaantuska 14 wuxuu muujinayaa muuqaalka burburka korantada ee madaxa birlabeedka Hard Disk-ga kumbuyuutarka.

Waqtiga boostada: Jul-08-2023